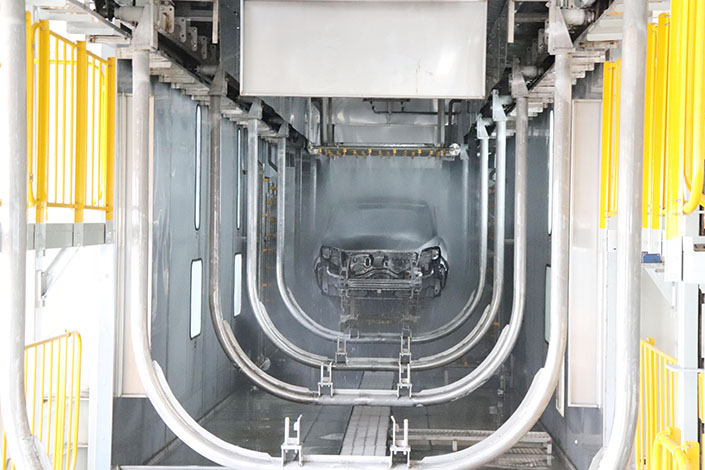

Mohala oa tlhahiso ea mofuta oa spray pele ho kalafo

Ho roala pele ho kenyelletsa ho fokotsa (ho fokotsa), ho tlosa mafome, ho senya likarolo tse tharo.Phosphating ke sehokelo bohareng, degreasing le mafome ho tlosoe ke mokhoa oa ho lokisetsa pele phosphating, kahoo ka tlhahiso ea tlhahiso, ha rea lokela ho nka feela mosebetsi oa phosphating e le sepheo, empa hape ho qala ho tloha litlhoko tsa boleng ba phosphating, ho etsa mosebetsi o motle ho phaella ho ho tlosoa ha oli le mafome, haholo-holo ela hloko tšusumetso e tšoanang pakeng tsa bona.

Ho theola boima ba 'mele

Ka nts'etsopele ea indasteri, ts'ireletso ea tikoloho le ntlafatso ea maemo a ts'ebetso e fetohile ntho e tloaelehileng ea batho.Ka hona, tlhoko ea ts'ireletso ea tikoloho e lokela ho tsotelloa ha ho khethoa baemeli.Ka hona, khetho ea moemeli oa ho tlosa oli e hloka ho itokisa habonolo, bokhoni ba ho senya bo matla, ha bo na sodium hydroxide, silicate, OP emulsifier le likarolo tse ling tseo ho leng thata ho li hloekisa mocheso oa kamore, ho bonolo ho hlatsoa mocheso oa kamore, ha li na chefo. lintho, ha li hlahise likhase tse kotsi, maemo a matle a ho sebetsa.Khetho ea ho tlosa mafome e hloka ho kenyelletsoa ha bahlahisi, li-corrosion inhibitors le li-inhibitors, ho ka ntlafatsa lebelo la ho tlosoa ha mafome, ho thibela workpiece ho tloha ho feta-corrosion le hydrogen embrittlement, e ka thibela hantle moholi oa acid.Na haholo-holo tšoaneloa ke acid moholi inhibiting, etsahalang ka tshebetso ya ho pickling acid moholi, kutu ea thepa le semela, e seng feela silafatsa tikoloho, 'me ka etsa hore ho bola leino, leino conjunctival redness, meokho, bohloko, omileng qoqotho, khohlela le matšoao a mang. , ka katleho thibela moholi oa acid, eseng feela tlhokahalo ea ts'ireletso ea tikoloho, kapa molemong oa bophelo bo botle ho litlhoko tsa mosebeletsi.

Ho hlatsoa metsi

Ho hlatsoa ka mor'a ho tlosoa ha oli le ho tlosoa ha mafome, le hoja e le ea ts'ebetso e thusang pele ho penta, e boetse e hloka ho baka tlhokomelo e lekaneng.Ka mor'a ho tlosoa ha oli le ho tlosoa ha mafome, holim'a workpiece ho bonolo ho khomarela li-surfactants tse seng tsa ionic le CL-.Haeba lintho tsena tse setseng li sa hloekisoe hantle, li ka baka phosphating filimi e fokolang, mefokolo ea mela, esita le phosphating.Ka hona, ho ntlafatsa boleng ba ho hlatsoa metsi ka mor'a ho tlosoa ha oli le ho tlosoa ha mafome, ho hlokahala hore u tsamaee ka li-rinses tse ngata, li-rinses tse peli, nako ea 1-2min, 'me u nke sebaka sa metsi khafetsa ho netefatsa hore boleng ba PH ba metsi bo pakeng tsa 5-7. .

Phosphating

Ho thoeng ke phosphating, e bua ka tšepe workpiece ka mor'a hore e na le dihydrogen phosphate acid e tharollo kalafo, karabelo ea lik'hemik'hale le ka holim'a eona ho hlahisa lera e tsitsitseng insoluble phosphate filimi, filimi bitsoa phosphating filimi.Morero o ka sehloohong oa filimi ea phosphating ke ho eketsa sekhomaretsi sa ho roala le ho ntlafatsa ho hanyetsa ha kutu ea ho roala.Ho na le mekhoa e mengata ea phosphating, ho latela mocheso oa phosphating, e ka aroloa ka mocheso o phahameng oa phosphating (90-98 ℃), mocheso o mahareng phosphating (60-75 ℃), phosphating e tlase ea mocheso (35-55 ℃) le mocheso o tloaelehileng. phosphating.

Boikemisetso

Theknoloji ea passivation ea filimi ea phosphating e sebelisoa haholo Amerika Leboea le linaheng tsa Europe.Theknoloji ea passivation e itšetlehile ka litšobotsi tsa filimi ea phosphating ka boeona.Filimi ea phosphating e tšesaane, ka kakaretso ho 1-4G / m2, boholo ba eona ha bo fete 10g / m2, sebaka sa mahala sa pore se seholo, 'me khanyetso ea kutu ea filimi ka boeona e lekanyelitsoe.Ba bang ba esita le ka ho omisa tshebetso ka potlako mosehla mafome, ka mor'a phosphating passivation koaloa kalafo, e ka ba phosphating filimi pore pepesa tšepe oxidation, kapa sebopeho sa passivation lera, phosphating filimi ka bapala ho tlatsa, oxidation, etsa phosphating filimi e tsitsitseng sepakapaka.

Ho omisa filimi ea phosphating

Ho omisa filimi ea phosphating ho ka bapala likarolo tse peli, ka lehlakoreng le leng, ke ho lokisetsa ts'ebetso e latelang ea ho tlosa metsi holim'a filimi ea phosphating, ka lehlakoreng le leng, ke ho ntlafatsa ho hanyetsa ha kutu ea filimi. ka mor'a ho roala.

Ho theha mohala oa ho koahela pele, moralo oa ts'ebetso o tlameha ho phethoa pele ho qaptjoa, ho etsa le ho kenya lisebelisoa tse sa tloaelehang.Ka hona, moralo oa ts'ebetso ke motheo oa mohala oa tlhahiso, 'me tsela e nepahetseng le e utloahalang e tla ba le phello e ntle mosebetsing oa tlhahiso le boleng ba sehlahisoa.

E sebelisoa bakeng sa mefuta eohle ea pente ea mosebetsi, mefuta e meng e ka etsoa ka mokhoa o ikhethileng.