Pele - kalafo bukana e bonolo tshebetso le othomathike pele ho kalafo tshebetso, ea ho qetela e arotsoe ka othomathike spray le jarolla ka ho iketsa dip spray mekhoa e 'meli.Sebaka sa ho sebetsa se tlameha ho sebetsoa ka holim'a metsi ho tlosa oli le mafome pele u fafatsa.Karolong ena ho sebelisitsoe mokelikeli o mongata, haholo-holo ho tlosa mafome, moemeli oa degreasing, ho lokisa tafole, phosphating agent joalo-joalo.

Karolong ea ts'ebetso kapa workshop pele ho mohala oa tlhahiso ea ho penta, tlhokomelo e lokela ho lefshoa ho thehoa ha theko e hlokahalang, lipalangoang, polokelo le tšebeliso ea tsamaiso e matla ea acid le alkali, ho fa basebetsi liaparo tse hlokahalang tse sireletsang, liaparo tse sireletsehileng le tse ka tšeptjoang, ho ts'oaroa, ho hlophisoa ha lisebelisoa, hammoho le nts'etsopele ea mehato ea phekolo ea tšohanyetso le mehato ea pholoso ha ho hlaha likotsi.Taba ea bobeli, karolong ea pretreatment ea mohala oa tlhahiso ea pente, ka lebaka la boteng ba khase e litšila, mokelikeli o litšila le lintho tse ling tse tharo tse litšila, ka hona, ho ea ka mehato ea ts'ireletso ea tikoloho, hoa hlokahala ho lokisa mouoane oa moea, ho tsoa ha metsi, lisebelisoa tse tharo tsa ho hloekisa litšila.

Boleng ba workpiece pele ho phekoloa e lokela ho ba e fapaneng ka lebaka la ho fapaneng pretreatment tharollo le barbotage tlhahiso mola tshebetso.Tshebetso e molemo ea workpiece, holim'a oli, mafome ho se etsa, e le ho thibela nako e khutšoanyane ho rusa hape, ka kakaretso e lokela ho ba pretreatment ka mor'a dithulaganyo tse 'maloa, phosphating kapa passivation kalafo: pele ho fafatsa phofo, hape e lokela ho ba le phosphating workpiece. bakeng sa ho omisa, mongobo oa eona o ka holimo.Tlhahiso e nyane ea sehlopha se le seng, ka kakaretso e sebelisa ho omisa moea oa tlhaho, ho omisa letsatsi, ho omisa moea.'Me bakeng sa mosebetsi o mongata oa phallo, ka kakaretso nka ho omisa mocheso o tlase, o sebelisa ontong kapa o omisa tsela.

Ho fafatsa tlhahiso ea mokhatlo oa ho roala phofo

Bakeng sa lisebelisoa tse nyane tsa batch, sesebelisoa sa ho phunya lerōle hangata se amoheloa, 'me bakeng sa sesebelisoa se seholo sa batch, sesebelisoa sa letsoho kapa sa othomathike se sebelisoa hangata.Ebang ke lerōle la letsoho kapa la othomathiki, taolo ea boleng e bohlokoa haholo.Ho etsa bonnete ba hore spraying workpiece phofo junifomo, e tsitsitseng botenya, ho thibela spray tšesaane, leakage spray, hlakola theoha le liphoso tse ling.

Coating tlhahiso line ka tshebetso, empa hape lokela ho ela hloko ho hook karolo ea workpiece, pele a kena ka folisa, lokela ho khomarela phofo ea eona ka hohle kamoo ho ka khonehang e tla letsa tsoa, thibela feteletseng phofo pheko ea hook, ba bang bakeng sa ho phekola tlosa masala phofo. pele ho mathata, e lokela ho ba ka nako e loketseng hlobolisa hook o na le solidified phofo filimi, conductive ho etsa bonnete ba hore hook e ntle, 'me palo ea lintho tse entsoeng ka matsoho ho phofo.

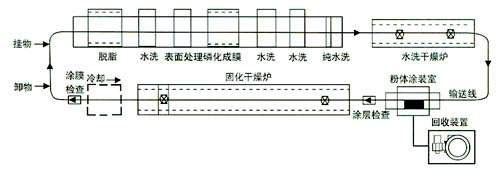

Tsamaiso ea tlhahiso ea mokhoa oa ho phekola moleng oa ho roala

Tshebetso ena e lokela ho ela hloko: sprayed workpiece, haeba e le sehlopha se senyenyane sa tlhahiso e le 'ngoe, ka sebōpi folisa pele ho ela hloko ho thibela oela phofo, tse kang phofshoana rubbing phenomenon, e lokela ho ba ka nako e loketseng spray phofo.Ha o baka, ts'ebetso e thata le mocheso, taolo ea nako, ela hloko ho thibela phapang ea mebala, ho feta ho baka kapa nako e khuts'oane e bakoang ke ho folisa ho sa lekaneng.

Bakeng sa palo e kholo ea phano ea othomathike ea workpiece, ka ho omisa tsela pele le ka hloko hlahloba hore na leakage spray, spray tšesaane kapa sebakeng phofo phenomenon, tse kang ho fumanoa likarolo sa tšoanelehang, e lokela ho koaloa ho thibela ho kena ka ho omisa tsela, kamoo ho ka khonehang. theola sefafatsi.Haeba workpiece e le 'ngoe e sa tšoanelehe ka lebaka la spray e tšesaane, e ka fafatsoa hape 'me ea tiisoa hape ka mor'a ho phekoloa.

Nako ea poso: Jan-17-2022